UBTECH Humanoid Robot

Industrial Application Solution

Industrial Application Solution

Solution Value

Humanoid robots can adapt to unstructured environments and assist in performing highly repetitive, risky, and complex tasks.

Cost-effective Deployment,

Intelligent Level Upgrade

Multi-Task Adaptability,

Customized Services

Efficient Management,

Better Quality Production

Long-term Usage,

Continuous Upgrades

Solution Value

Humanoid robots can adapt to unstructured environments and assist in performing highly repetitive, risky, and complex tasks.

Cost-effective Deployment,

Intelligent Level Upgrade

Multi-Task Adaptability,

Customized Services

Efficient Management,

Better Quality Production

Long-term Usage,

Continuous Upgrades

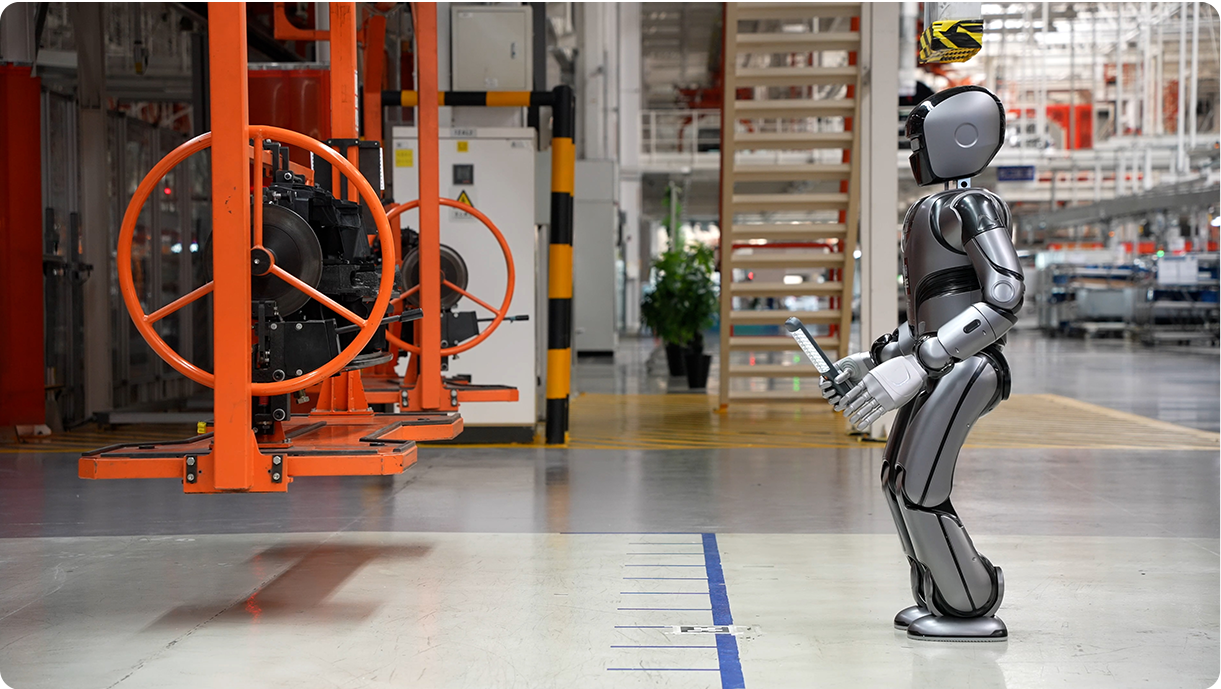

Walker S Series Capable for Task Reasoning & Execution

Walker S Series Capable for

Task Reasoning & Execution

Task Reasoning & Execution

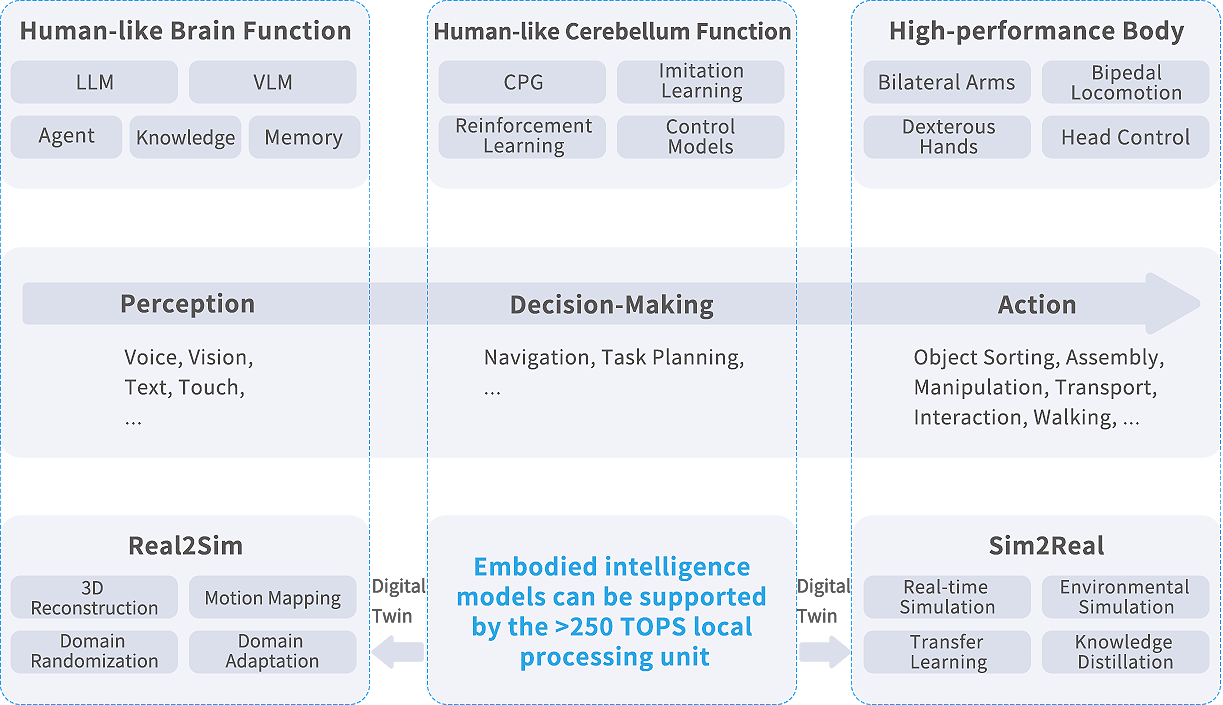

Continuous Breakthroughs in "Brain","Cerebellum","Embodiment" and Other Key Technologies

Industrial Application Scenarios

Parcel

Handling

Handling

SPS

Sorting

Sorting

Quality

Inspection

Inspection

Screw-bolt

Tightening

Tightening

Part

Assembly

Assembly

Process Material

Handling

Handling

The Walker S series can autonomously navigate and carry loads between different pallets and conveyor lines, carrying parcels of various sizes and thereby reducing the physical injuries to handlers caused by long-term high-load lifting and carrying.

In the SPS scenario, Walker S can achieve automated sorting, picking up and placing two types of components to specified locations within 10 seconds, so as to enhance the accuracy of sorting and optimizing the production process.

The Walker S series is capable of conducting visual quality inspections on completely or partially assembled modules in moving automotive production lines, with an accuracy rate exceeding 99%, ensuring the delivery of high-quality products.

Walker S can use an electric screwdriver to tighten screws on car doors or other parts, achieving refined repetitive operations and reducing the repetitive labor for workers.

Capable of performing tasks such as affixing car logos, configuring firmware updates, and printing labels, Walker S can help to enhance the consistency of installation accuracy.

Walker S can undertake tasks such as automated application of glass adhesive, thereby preventing harm to workers from long-term exposure to such substances.

Industrial Application Cases

UBTECH Robotics x BYD

Walker S1 has entered the BYD factory to perform handling tasks and has completed the world's first one-stop autonomous logistics application that humanoid robots coordinate with autonomous logistics vehicles, AMRs/AGVs and intelligent manufacturing management systems, marking a new milestone in humanoid robot factory training.

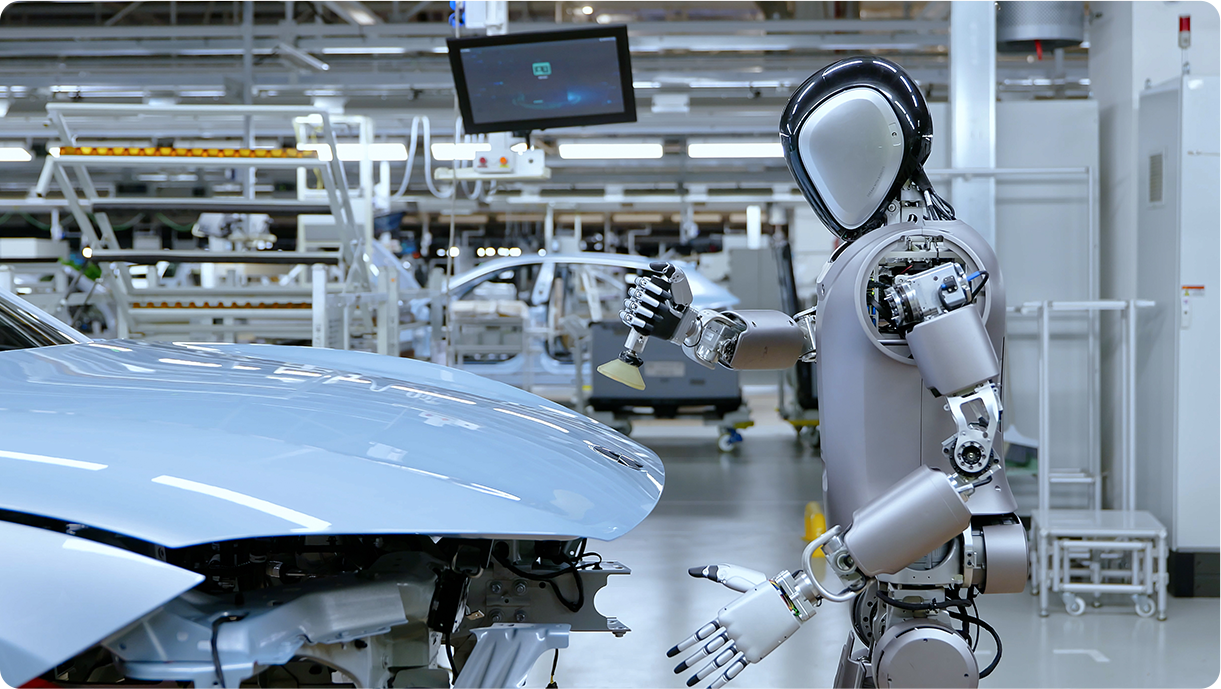

UBTECH Robotics x NIO

Walker S was deployed in the final assembly workstation of NIO's advanced manufacturing base F2, marking the world's first instance of a humanoid robot collaborating with humans to complete automotive assembly and quality inspection tasks on a factory production line.

UBTECH Robotics x Geely Auto

Walker S Lite demonstrated its Parcel-tote Handling capabilities in the smart warehouse of Zeekr automotive factory for the first time in China, performing three weeks of training at the CTU loading workstation.

UBTECH Robotics x Dongfeng Liuzhou Motor

Walker S conducted a series of tasks in the automotive manufacturing process, including inspections, fluid filling and the application of car emblems etc. Combined with the latest AI technology, humanoid robots could provide better solutions through training.

UBTECH Robotics x FAW-Volkswagen Qingdao

FAW-Volkswagen opened its "National Intelligent Manufacturing Demonstration Factory" production line application scenarios in Qingdao to UBTECH, introducing Walker S Lite to perform quality inspection tasks so as to enhance FAW-Volkswagen's manufacturing automation level.

Partner with us and

join the revolutionary humanoid robot industrialization!

Partner with us and join the revolutionary humanoid robot industrialization!

Please reach out for more request or become a partner!

Contact Us